Overview Portfolio

GALLERY

INSTALLATION

GALLERY INSTALLATION

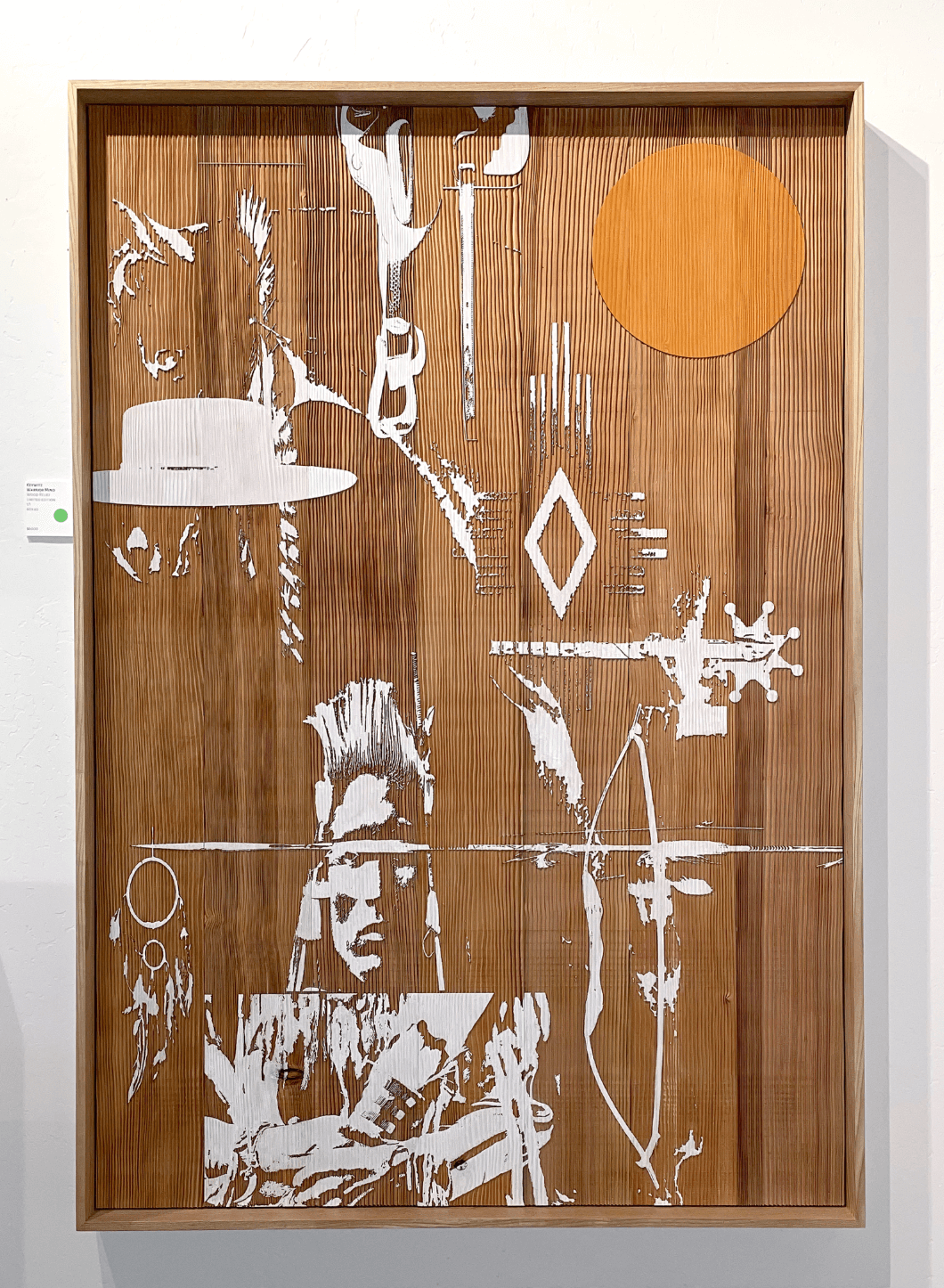

Custom art fabrication and installation that was completed and installed for an art gallery in Steamboat Springs, Colorado. The installation of the art was very challenging because the gallery walls were brick and mortar, that was very old and brittle. The art installation solution was to use Tapcon concrete screws. When using a concrete drill bit for a certain size hole, under these conditions, it was important to understand that the pilot hole would be larger than the actual drill bit diameter because of the brittleness of the masonry. The solution in this case was to hammer-in plastic anchors into the oversized holes so that the Tapcon could perform its intended structural function.

Custom art fabrication and installation that was completed and installed for an art gallery in Steamboat Springs, Colorado. The installation of the art was very challenging because the gallery walls were brick and mortar, that was very old and brittle. The art installation solution was to use Tapcon concrete screws. When using a concrete drill bit for a certain size hole, under these conditions, it was important to understand that the pilot hole would be larger than the actual drill bit diameter because of the brittleness of the masonry. The solution in this case was to hammer-in plastic anchors into the oversized holes so that the Tapcon could perform its intended structural function.

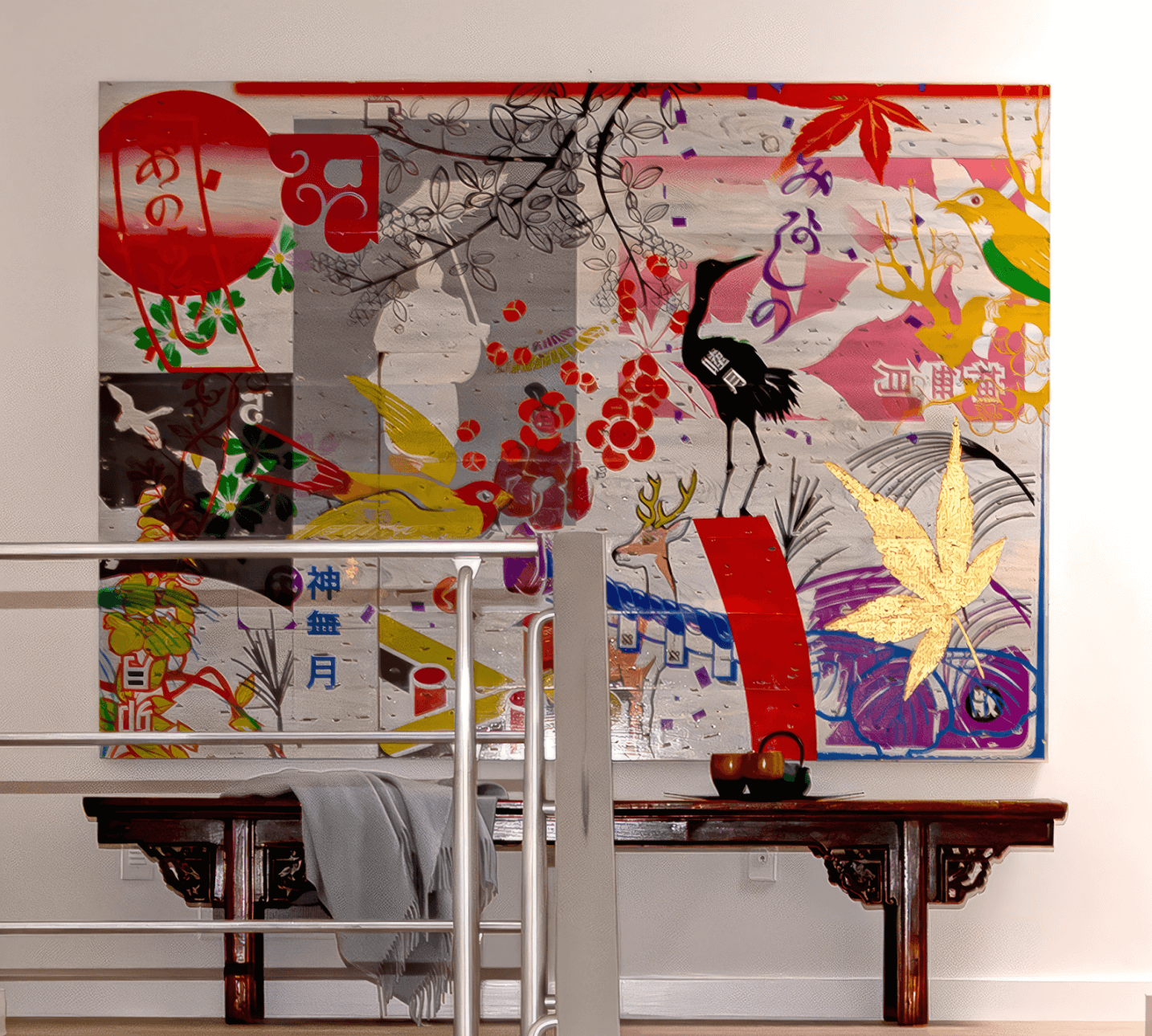

Custom fabrication and art installation created for a client in Forest Hills, Washington, D.C. The art was created by scanning and photographing elements of Japanese Hanafuda cards. The image elements were then color altered and transferred to the surface using a pigment-based ink hand transfer technique. The maple leaf in the right corner of the piece was laser etched into the surface of the wood and then Dutch metal was inlaid into the laser impression. The installation was completely unique as well. Each individual section of wood had to be attached into the stud locations within the wall, which required a special 3d printed jig to ensure that each hole would be drilled at the same angle through the material to ensure proper structural performance.